ANSI/ASME B16.5 & B16.47 Ring Type Joint Flanges

PDF: Ring Joint Facings – ASME/ANSI B16.5 & B16.47

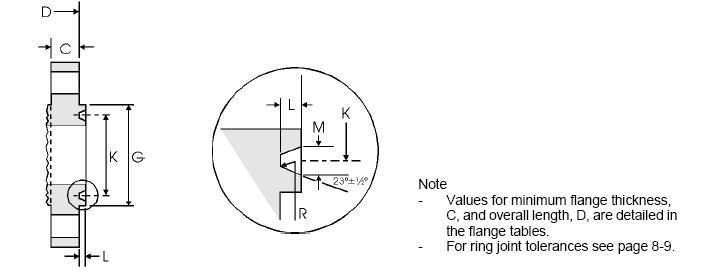

Note

-Values for minimum flange thickness, C, and overall length, D, are detailed in the flange tables.

-For ring joint tolerances see page 8-9.

Ring joint facing dimensions -ASME/ANSI B16.5 and B16.47 Series A (MSS SP-44) and Series B (API 605)

|

Class (lb) |

Groove/RingNumber |

Raised Face |

Groove |

|||||||||

|

150 |

300 |

400 |

600 |

900 |

1500 |

2500 |

||||||

|

Nominal Pipe Size (NPS) |

Face Diameter min |

Pitch Diameter |

Depth1 |

Width |

Radius at Bottom |

|||||||

|

in mm |

in mm |

in mm |

in mm |

in mm |

||||||||

|

ASME/ANSI B16.5 covers NPS 1/2 to 24: |

||||||||||||

|

1/2 |

Use Class 600 for sizes < 3 1 /2 |

1/2 |

Use Class 1500 for sizes < 2 1/2 |

R11 |

2.000 50.80 |

1.344 34.14 |

0.219 5.56 |

0.281 7.14 |

0.03 0.76 |

|||

|

1/2 |

R12 |

2.380 60.45 |

1.562 39.67 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

3/4 |

3/4 |

R13 |

2.500 63.50 |

1.688 42.88 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

|||||

|

1/2 |

R13 |

2.560 65.02 |

1.688 42.88 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

3/4 |

R14 |

2.620 66.55 |

1.750 44.45 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

1 |

R15 |

2.500 63.50 |

1.875 47.63 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

1 |

1 |

R16 |

2.750 69.85 |

2.000 50.80 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

|||||

|

1 |

R16 |

2.810 71.37 |

2.000 50.80 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

3/4 |

R16 |

2.880 73.15 |

2.000 50.80 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

11/4 |

R17 |

2.880 73.15 |

2.250 57.15 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

11/4 |

11/4 |

R18 |

3.120 79.25 |

2.375 60.33 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

|||||

|

11/4 |

R18 |

3.190 81.03 |

2.375 60.33 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

1 |

R18 |

3.250 82.55 |

2.375 60.33 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

11/2 |

R19 |

3.250 82.55 |

2.562 65.07 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

11/2 |

11/2 |

R20 |

3.560 90.42 |

2.688 68.28 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

|||||

|

11/2 |

R20 |

3.620 91.95 |

2.688 68.28 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

11/4 |

R21 |

4.000 101.60 |

2.844 72.24 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||

|

2 |

R22 |

4.000 101.60 |

3.250 82.55 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

2 |

2 |

R23 |

4.250 107.95 |

3.250 82.55 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

|||||

|

11/2 |

R23 |

4.500 114.30 |

3.250 82.55 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||

|

2 |

R24 |

4.880 123.95 |

3.750 95.25 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||

|

21/2 |

R25 |

4.750 120.65 |

4.000 101.60 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

21/2 |

21/2 |

R26 |

5.000 127.00 |

4.000 101.60 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

|||||

|

2 |

R26 |

5.250 133.35 |

4.000 101.60 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||

|

Class (lb) |

Raised Face |

Groove |

||||||||||||||

|

150 |

300 |

400 |

600 |

900 |

1500 |

2500 |

e/Ringmber |

|||||||||

|

Nominal Pipe Size (NPS) |

GroovNu |

Face Diameter min |

Pitch Diameter |

Depth1 |

Width |

Radius at Bottom |

||||||||||

|

in mm |

in mm |

in mm |

in mm |

in mm |

||||||||||||

|

Use Class 600 for sizes < 3 1 /2 |

21/2 |

R27 |

5.380 136.65 |

4.250 107.95 |

0.31 27.92 |

0.469 11.91 |

0.03 0.76 |

|||||||||

|

21/2 |

R28 |

5.880 149.35 |

4.37511 1.13 |

0.375 9.53 |

0.531 13.49 |

0.06 1.52 |

||||||||||

|

3 |

R29 |

5.250 133.35 |

4.500 114.30 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||||||

|

-2 |

-2 |

R30 |

– |

4.625 117.48 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

|||||||||

|

32 |

32 |

R31 |

5.750 146.05 |

4.875 123.83 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

|||||||||

|

3 |

R31 |

6.120 155.45 |

4.875 123.83 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||||

|

3 |

R32 |

6.620 168.15 |

5.000 127.00 |

0.375 9.53 |

0.531 13.49 |

0.06 1.52 |

||||||||||

|

31/2 |

R33 |

6.060 153.92 |

5.188 131.78 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||||||

|

31/2 |

31/2 |

R34 |

6.250 158.75 |

5.188 131.78 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

|||||||||

|

3 |

R35 |

6.620 168.15 |

5.375 136.53 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||||

|

4 |

R36 |

6.750 171.45 |

5.875 149.23 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||||||

|

4 |

4 |

4 |

R37 |

6.880 174.75 |

5.875 149.23 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||

|

4 |

R37 |

7.120 180.85 |

5.875 149.23 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||||

|

4 |

R38 |

8.000 203.20 |

6.1881 57.18 |

0.438 11.13 |

0.656 16.66 |

0.06 1.52 |

||||||||||

|

4 |

R39 |

7.620 193.55 |

6.375 161.93 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||||

|

5 |

R40 |

7.620 193.55 |

6.750 171.45 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||||||

|

5 |

5 |

5 |

R41 |

8.250 209.55 |

7.125 180.98 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||

|

5 |

R41 |

8.500 215.90 |

7.125 180.98 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||||

|

5 |

R42 |

9.500 241.30 |

7.500 190.50 |

0.500 12.70 |

0.781 19.84 |

0.06 1.52 |

||||||||||

|

6 |

R43 |

8.620 218.95 |

7.625 193.68 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||||||

|

5 |

R44 |

9.000 228.60 |

7.625 193.68 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||||

|

6 |

6 |

6 |

R45 |

9.500 241.30 |

8.312 211.12 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||

|

6 |

R45 |

9.500 241.30 |

8.312 211.12 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||||

|

6 |

R46 |

9.750 247.65 |

8.312 211.12 |

0.375 9.53 |

0.531 13.49 |

0.06 1.52 |

||||||||||

|

6 |

R47 |

11.000 279.40 |

9.000 228.60 |

0.500 12.70 |

0.781 19.84 |

0.06 1.52 |

||||||||||

|

8 |

R48 |

10.750 273.05 |

9.750 247.65 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||||||

|

8 |

8 |

8 |

R49 |

11.880 301.75 |

10.625 269.88 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||

|

8 |

R49 |

12.120 307.85 |

10.625 269.88 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||||

|

8 |

R50 |

12.500 317.50 |

10.625 269.88 |

0.438 11.13 |

0.656 16.66 |

0.06 1.52 |

||||||||||

|

8 |

R51 |

13.380 339.85 |

11.000 279.40 |

0.562 14.27 |

0.906 23.01 |

0.06 1.52 |

||||||||||

|

10 |

R52 |

13.000 330.20 |

12.000 304.80 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||||||

|

10 |

10 |

10 |

R53 |

14.000 355.60 |

12.750 323.85 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||

|

10 |

R53 |

14.250 361.95 |

12.750 323.85 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||||||

|

10 |

R54 |

14.620 371.35 |

12.750 323.85 |

0.438 11.13 |

0.656 16.66 |

0.06 1.52 |

||||||||||

|

Ring joint facing dimensions -ASME/ANSI B16.5 |

||||||||||||||||

|

Class (lb) |

Raised Face |

Groove |

||||||||||

|

150 |

300 |

400 |

600 |

900 |

1500 |

2500 |

e/Ringmber |

|||||

|

Nominal Pipe Size (NPS) |

GroovNu |

Face Diameter min |

Pitch Diameter |

Depth1 |

Width |

Radius at Bottom |

||||||

|

in mm |

in mm |

in mm |

in mm |

in mm |

||||||||

|

10 |

R55 |

16.750 425.45 |

13.500 342.90 |

0.688 17.48 |

1.188 30.18 |

0.09 2.29 |

||||||

|

12 |

R56 |

16.000 406.40 |

15.000 381.00 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

12 |

12 |

12 |

R57 |

16.250 412.75 |

15.000 381.00 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||

|

12 |

R57 |

16.500 419.10 |

15.000 381.00 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||||

|

12 |

R58 |

17.250 438.15 |

15.000 381.00 |

0.562 14.27 |

0.906 23.01 |

0.06 1.52 |

||||||

|

14 |

R59 |

16.750 425.45 |

15.625 396.88 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

12 |

R60 |

19.500 495.30 |

16.000 406.40 |

0.688 17.48 |

1.312 33.32 |

0.09 2.29 |

||||||

|

14 |

14 |

14 |

R61 |

18.000 457.20 |

16.500 419.10 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||

|

14 |

R62 |

18.380 466.85 |

16.500 419.10 |

0.438 11.13 |

0.656 16.66 |

0.06 1.52 |

||||||

|

14 |

R63 |

19.250 488.95 |

16.500 419.10 |

0.625 15.88 |

1.062 26.97 |

0.09 2.29 |

||||||

|

16 |

R64 |

19.000 482.60 |

17.875 454.03 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

16 |

16 |

16 |

R65 |

20.000 508.00 |

18.500 469.90 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||

|

16 |

R66 |

20.620 523.75 |

18.500 469.90 |

0.438 11.13 |

0.656 16.66 |

0.06 1.52 |

||||||

|

16 |

R67 |

21.500 546.10 |

18.500 469.90 |

0.688 17.48 |

1.188 30.18 |

0.09 2.29 |

||||||

|

18 |

R68 |

21.500 546.10 |

20.375 517.53 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

18 |

18 |

18 |

R69 |

22.620 574.55 |

21.000 533.40 |

0.312 7.92 |

0.469 11.91 |

0.03 0.76 |

||||

|

18 |

R70 |

23.380 593.85 |

21.000 533.40 |

0.500 12.70 |

0.781 19.84 |

0.06 1.52 |

||||||

|

18 |

R71 |

24.120 612.65 |

21.000 533.40 |

0.688 17.48 |

1.188 30.18 |

0.09 2.29 |

||||||

|

20 |

R72 |

23.500 596.90 |

22.000 558.80 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

20 |

20 |

20 |

R73 |

25.000 635.00 |

23.000 584.20 |

0.375 9.53 |

0.531 13.49 |

0.06 1.52 |

||||

|

20 |

R74 |

25.500 647.70 |

23.000 584.20 |

0.500 12.70 |

0.781 19.84 |

0.06 1.52 |

||||||

|

20 |

R75 |

26.500 673.10 |

23.000 584.20 |

0.688 17.48 |

1.312 33.32 |

0.09 2.29 |

||||||

|

24 |

R76 |

28.000 711.20 |

26.500 673.10 |

0.250 6.35 |

0.344 8.74 |

0.03 0.76 |

||||||

|

24 |

24 |

24 |

R77 |

29.500 749.30 |

27.250 692.15 |

0.438 11.13 |

0.656 16.66 |

0.06 1.52 |

||||

|

24 |

R78 |

30.380 771.65 |

27.250 692.15 |

0.625 15.88 |

1.062 26.97 |

0.09 2.29 |

||||||

|

Class (lb) |

Groove/RingNumber |

Raised Face |

Groove |

|||||||||

|

150 |

300 |

400 |

600 |

900 |

1500 |

2500 |

||||||

|

Nominal Pipe Size (NPS) |

Face Diameter min |

Pitch Diameter |

Depth1 |

Width |

Radius at Bottom |

|||||||

|

in mm |

in mm |

in mm |

in mm |

in mm |

||||||||

|

24 |

R79 |

31.250 793.75 |

27.250 692.15 |

0.812 20.62 |

1.438 36.53 |

0.09 2.29 |

||||||

|

MSS SP-44 only, covers NPS 22: |

||||||||||||

|

22 |

22 |

22 |

R81 |

27.000 685.80 |

25.000 635.00 |

0.438 11.13 |

0.594 15.09 |

0.06 1.52 |

||||

|

ASME/ANSI B16.47 (MSS SP-44 & API 605) covers NPS 26 to 36. (There are no ring joint facings >NPS 36) |

||||||||||||

|

26 |

26 |

26 |

R93 |

31.880 809.75 |

29.500 749.30 |

0.500 12.70 |

0.781 19.84 |

0.06 1.52 |

||||

|

28 |

28 |

28 |

R94 |

33.880 860.55 |

31.500 800.10 |

0.500 12.70 |

0.781 19.84 |

0.06 1.52 |

||||

|

30 |

30 |

30 |

R95 |

36.120 917.45 |

33.750 857.25 |

0.500 12.70 |

0.781 19.84 |

0.06 1.52 |

||||

|

32 |

32 |

32 |

R96 |

38.750 984.25 |

36.000 914.40 |

0.562 14.27 |

0.906 23.01 |

0.06 1.52 |

||||

|

34 |

34 |

34 |

R97 |

40.750 1035.1 |

38.000 965.20 |

0.562 14.27 |

0.906 23.01 |

0.06 1.52 |

||||

|

36 |

36 |

36 |

R98 |

43.000 1092.2 |

40.250 1022.4 |

0.562 14.27 |

0.906 23.01 |

0.06 1.52 |

||||

|

26 |

R100 |

32.750 831.85 |

29.500 749.30 |

0.688 17.48 |

1.188 30.18 |

0.09 2.29 |

||||||

|

28 |

R101 |

35.000 889.00 |

31.500 800.10 |

0.688 17.48 |

1.312 33.32 |

0.09 2.29 |

||||||

|

30 |

R102 |

37.250 946.15 |

33.750 857.25 |

0.688 17.48 |

1.312 33.32 |

0.09 2.29 |

||||||

|

32 |

R103 |

39.500 1003.3 |

36.000 914.40 |

0.688 17.48 |

1.312 33.32 |

0.09 2.29 |

||||||

|

34 |

R104 |

42.000 1066.8 |

38.000 965.20 |

0.812 20.62 |

1.438 36.53 |

0.09 2.29 |

||||||

|

36 |

R105 |

44.250 1124.0 |

40.250 1022.4 |

0.812 20.62 |

1.438 36.53 |

0.09 2.29 |

||||||

Notes -Ring joint gasket dimensions conform to ASME B16.20 (not covered in this summary). -Use Class 600 lb in sizes NPS 1/2 to NPS 31/2 for Class 400 lb. -Use Class 1500 lb in sizes NPS 1/2 to NPS 21/2 for Class 900 lb. -Tolerances are as shown in the table below. 1 The height of the raised portion is equal to the depth of groove dimension L, but is not subject to the tolerances for L. 2 Ring joints with lapped flanges in Classes 300 lb and 600 lb use R30 instead of R31.

Ring joint facing tolerances (ASME/ANSI B16.5 and B16.47)

|

Dimension |

Range |

Tolerance |

|

|

in |

mm |

||

|

L (depth) |

All |

+0.016, -0 |

+0.406, -0 |

|

M (width) |

All |

±0.008 |

±0.203 |

|

K (pitch diameter) |

All |

±0.005 |

±0.127 |

|

R < 0.06 in |

+0.03, -0 |

+0.762, -0 |

|

|

R (radius at bottom) |

R > 0.06 in |

±0.03 |

±0.762 |

|

> NPS 26 |

maximum quoted |

||

|

D (overall length) for flanges with ring joint |

< NPS 10 |

±0.06 |

±1.52 |

|

> NPS 12 |

±0.12 |

±3.05 |

|