How to deal with high pressure flange seal leakage?

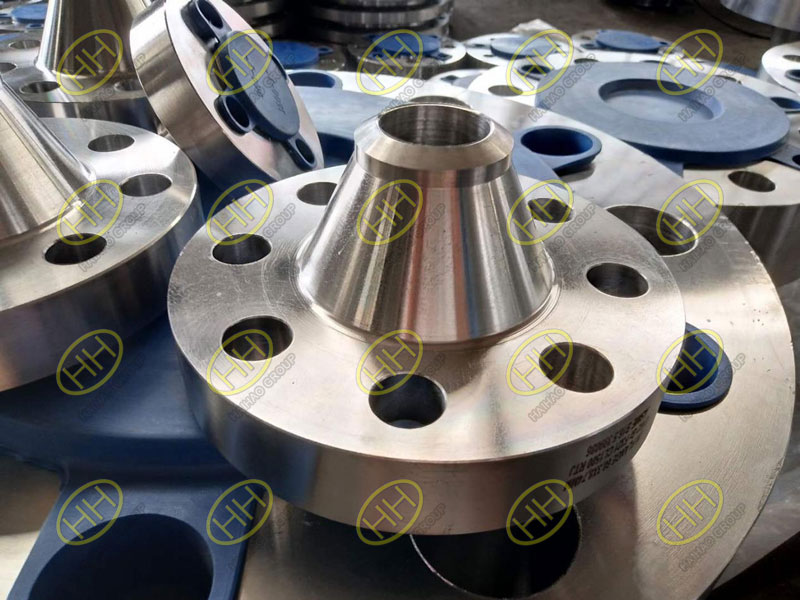

The sealing structure of the high-pressure flange lens pad is as follows: the sealing surfaces on both sides of the lens pad are spherical surfaces, the beveled surface of the tube end contacts the tapered sealing surface, and the angle between the tube end and the lens pad is about 20 degrees. The initial state is a complete loop. Under the action of the bolt pre-tightening force, the lens pad is plastically deformed at the contact point, and the loop becomes an annular belt, ensuring reliable sealing of the high-pressure pipeline.

And such high-pressure flanges leak more during use, so this kind of high-pressure flange leakage is more common, today see what methods can appropriately reduce the occurrence of this situation.

1. Elimination method

The most basic way to repair the sealing element to eliminate leakage is to increase the pre-tightening force of the flange bolts and repair or replace the sealing element. The high-pressure lens pad is easy to disassemble and low in price. It is generally handled by removing the light knife or replacing it with a new one. For high-pressure pipelines, especially large-diameter high-pressure pipelines, it is difficult to replace, dismantle, transfer, and manufacture, and it is not economically cost-effective. It is advisable to adopt on-site repair methods. If the sealing surface of the pipe end is partially damaged, it can be repaired by spot welding the damaged part and then grinding the sealing surface and performing coloring or magnetic particle inspection;

2. Leakage reduction measures

The vast majority of lens gasket sealing leakage is interface leakage, which occurs at the interface between the lens gasket sealing spherical surface and the tube end tapered sealing surface. It is mainly caused by pipeline vibration, poor assembly, medium corrosion, process fluctuations and other reasons. We took effective preventive measures based on the cause of the leakage and the actual situation on the spot.

Vibration reduction is the primary cause of damage to the high-pressure flange lens gasket seal. The vibration of the pipeline is mainly caused by the vibration of adjacent equipment, the pulsation of the air flow generated by the fluid flowing in the pipeline, and the excitation vibration of pipe fittings (such as elbows and valves). Therefore, when the direction and structural size of the pipeline cannot be changed due to conditional constraints, most of the methods are used to strengthen the pipeline, and pipe racks and pipe clamps are added to the elbows, valves, reducing short sections and large spans. Repair welding and the weld seam of the pipe frame separated from the foundation embedded iron, and use angle steel or channel steel to reinforce the original pipe frame to improve its rigidity; replace all the pipe clamps and bolts, and use double nuts to fix the loose.