Kammprofile gasket with graphite layer were finished

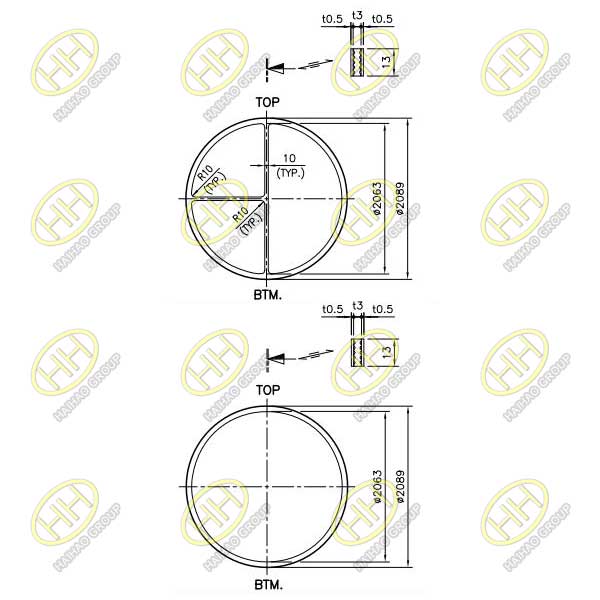

The product description given by the client is: GASKET, t4 x Ø2089 / Ø2063 (T-TYPE), 9, 10, KAMMPROFILE GASKET (t4) – GROOVED METAL: 316L S.S (t3), GRAPHITE LAYER: t0.5 ON BOTH SIDE. This is a set of two gaskets. The attached drawing is as follows:

According to the drawings provided by the client, the following is the process photos of our processing kammprofile shape. Generally, this kind of gasket is first processed into a concentric 90 degree included angle on the two sides of the metal flat gasket with a precision lathe or a special milling machine to form a wave shaped serrated groove. Since the contact with other sealing surfaces is a line contact of multiple concentric circles, it has a labyrinth sealing function.

This size is relatively large, with the OD of nearly 2.1m. We have specially made wooden case for them. However, we also need to consider that the internal width of the container is about 2.35m, so the length and width of the customized wooden case is 2.22M to meet the requirements of loading. In addition, in order to prevent the gasket from moving and deforming during transportation, we also fixed the gasket properly in the wooden box, as the following photo.