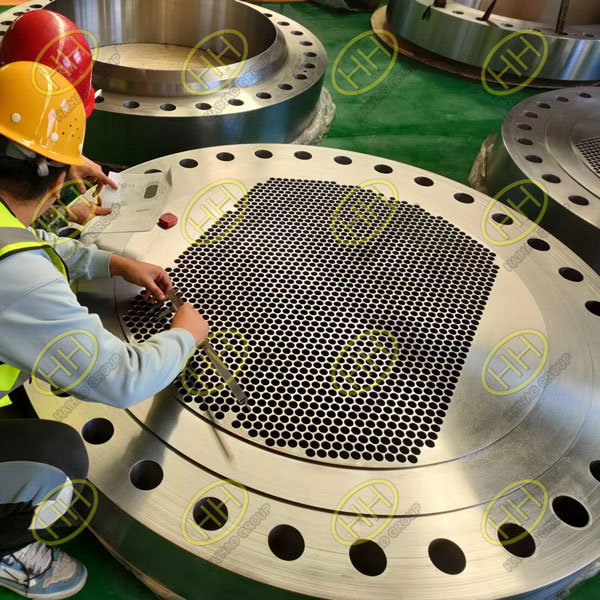

tube sheet inspection

Tube sheet, which is a round steel plate with holes slightly larger than the outer diameter of the tube, is used to fix the tube and seal the medium in the heat exchanger. It is a kind of flange that can penetrate the pipe and fix it by welding.

The precision of tube sheet processing, especially the tolerance of tube hole spacing and pipe diameter, perpendicularity and finish, greatly affects the assembly and use performance of the above listed chemical equipment.

The following photos show that our factory’s inspectors are conducting tube sheet inspection.

The order description is “Tube Sheet (OD: 1700rnm x Thk: 220mrn), SA-350 LF2 CL. 1. as per attached TDC’s&Drawing”, and relevant drawings and technical documents are also provided. After the completion of production, we strictly inspect the dimensional tolerance according to the data provided by the drawings, and all the tolerances are within the required range.

During the inspection of tubesheet, the main inspection indicators are hole position, hole diameter tolerance, hole internal finish, burr, groove cutting position, etc., which are also strictly required in the technical documents of customer orders. For double tubesheet, more attention shall be paid to the hole location during the inspection process, and the hole location fit of the two tubesheet is very important. Generally, it can be guaranteed by numerical control drilling machine. Compared with thick plates, the perpendicularity of holes over 300mm is very important. These large diameter thick plates need more sophisticated tools and equipment.