The benefits of applying 625 surfacing welding on the flange

In the realm of pipeline engineering and industrial applications, ensuring the utmost durability and longevity of flanges is of paramount importance. At Haihao Group, we continuously strive to provide innovative solutions to meet our clients’ evolving needs. Introducing the cutting-edge 625 surfacing welding process, a game-changer in flange performance and reliability.

What is 625 Surfacing Welding Process?

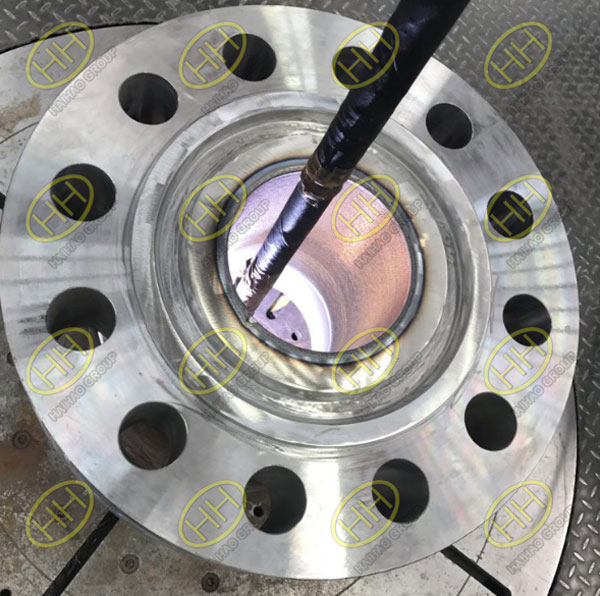

The 625 surfacing welding process involves overlaying a layer of high-quality Alloy 625 material onto the surface of the flange. Alloy 625, known for its exceptional corrosion resistance, high strength, and outstanding weldability, forms a protective shield over the flange, enhancing its capabilities to withstand harsh environments and challenging operating conditions.

The Benefits of 625 Surfacing Welding Process on Flanges:

Unmatched Corrosion Resistance:

The primary advantage of utilizing the 625 surfacing welding process lies in the unparalleled corrosion resistance it imparts to flanges. In corrosive environments, such as those encountered in oil and gas production, chemical processing, and marine applications, the 625 surfacing acts as a robust barrier, shielding the flange from corrosion, erosion, and chemical attacks. This feature significantly prolongs the service life of the flange, reducing maintenance costs and downtime.

Superior Strength and Mechanical Properties:

With Alloy 625’s impressive mechanical properties, the surfacing welding process reinforces the flange’s structural integrity and strength. Flanges subjected to high-pressure systems or heavy loads benefit from the enhanced mechanical properties, ensuring reliable performance even in demanding conditions.

Excellent Weldability and Compatibility:

The 625 surfacing welding process seamlessly integrates the overlay material with the base flange, providing excellent weldability and compatibility. The cohesive bond between the two materials eliminates the risk of delamination or detachment, ensuring a secure and robust connection.

Versatility in Application:

The flexibility of the 625 surfacing welding process makes it suitable for a wide range of flange sizes, types, and materials. Whether it’s carbon steel, stainless steel, or alloy flanges, the surfacing process can be tailored to meet specific project requirements.

Cost-Effective Solution:

By extending the lifespan of flanges and minimizing the need for frequent replacements or repairs, the 625 surfacing welding process proves to be a cost-effective investment in the long run. It enhances the reliability and efficiency of pipeline systems, contributing to higher productivity and reduced operational expenses.

Elevate Your Flange Performance with Haihao Group:

At Haihao Group, we take pride in being at the forefront of technological advancements in the piping and flange industry. Our 625 surfacing welding process empowers flanges to conquer the challenges posed by harsh environments and demanding applications.

Choose Haihao Group as your trusted partner in enhancing flange performance with the 625 surfacing welding process. Our team of skilled professionals and cutting-edge facilities ensure that your flanges are fortified with the best solutions available, guaranteeing outstanding results and optimal performance in your projects. Contact us today to experience the difference of excellence in flange technology with Haihao Group. Let us take your projects to new heights of success and reliability.