Production process of forged flange

What is a forged flange?

Forged flange is one of the best mechanical properties of flange products.Its raw material is usually tube billet.After cutting,it is beaten continuously to eliminate segregation and looseness in ingot.The price and mechanical properties are one grade higher than those of common cast flange.Forging flange has good pressure and temperature resistance,which is generally suitable for high pressure and high temperature working environment.

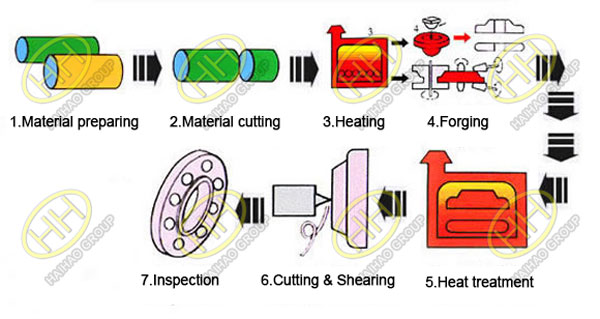

Production process of forged flange:

The process of forging process is composed of the following procedure,which is to select the high quality steel billet,heat,forming and forge to cool down.The forging process has a free forging,die forging,and tire forging.In production,different forging methods are adopted according to the quality and quantity of forgings.The main anticorrosion treatments for forged flange are oiling and galvanizing.

Free forging:

The free forging equipment is equipped with pneumatic hammer,steam air hammer and hydraulic press,which are suitable for the production of small and large forgings.High productivity,easy operation,easy mechanization and automation.The size of die forging is high,the machining allowance is small,and the fabric of the forging is more reasonable,which can further improve the service life of the parts.

The basic process of free forging:when forging,the shape of the forging is gradually forged through some basic deformation process.The basic process of forging and forging is upbold,long,piercing,bending and cutting.

Upset upsetting is the operation process that reduces the height of the raw material and increases the cross section.This process is used for forging gear billets and other disc shaped forgings.The heading is divided into full heading and partial forging.

The length of the shaft is increased by the length of the billet,the forging process of the reduction of the section is usually used to produce the spindle such as the lathe spindle,the connecting rod and so on.

- The forging process of punching holes through holes or holes in the blank.

- The forging process that bends the blank to a certain Angle or shape.

- Twist the process of turning a part of the billet into a certain angle.

- The forging process of cutting down the raw material or cutting head.

Die forging:

The die forging is known as the forging of the model, which is placed in the forging of the forging machine which is fixed on the die forging equipment.

The basic process of die forging:material,heating,pre-forging,finishing,finishing,cutting,trimming and blasting.The common technique is to upset,pull,bend,punch and form.

The commonly used die forging equipment has die forging hammer,hot die forging press,flat forging machine and friction press.

Froged flange materials:

The main materials of forging flanges in Haihao Group are carbon steel,stainless steel and alloy steel,there are the materials standard:

Carbon steel:ASTM A105,A350 LF2,SS400,P235GH,P250GH,C22.8,Q235,20#,16Mn.

Stainless steel:ASTM A182 F304,F304L,F316,F316L,F321,F347,F310,F44,F51 etc.

Alloy steel:ASTM A694 F42,F46,F52,F56,F60,F65,F70,A182 F5,F9,F91,F12,F11,F22 etc.

Haihao Group supply forged flanges according to national standards,electric standard,American standard,German standard,Japanese standard,European standard,Russian standards and so on.The standards as follows:ANSI/ASME B16.5,B16.47,B16.48;AWWA C207;API 6A/6B/6BX;DIN 2527,2573,2576,2631,2632,2633,2634,2635,2566,2642;EN 1092;BS 4504;JIS B2220;GOST 12820,GOST 12821;SABS 1123;AS 1219 etc.

Difference between forged flange and casing flange:

Forged flange is generally lower in carbon content than cast flange,less easy to rust,better streamlined forging,compact structure and better mechanical properties than cast flange.

Improper forging process will also lead to large or uneven grains,hardening cracks and higher forging cost than casting flange.

Forgings can withstand higher shear and tensile forces than castings.

The advantages of castings are that they can produce more complex shapes and have lower cost.

The advantages of forgings are that the internal structure is uniform and there are no harmful defects such as blowhole and inclusion in the casting.

The difference between casting flange and forging flange can be distinguished from the production process,for example,centrifugal flange belongs to casting flange.

Centrifugal flange is a kind of flange produced by precision casting method.Compared with common sand casting,this casting method has much finer structure and much better quality.It is not easy to have loose structure,pore and trachoma.

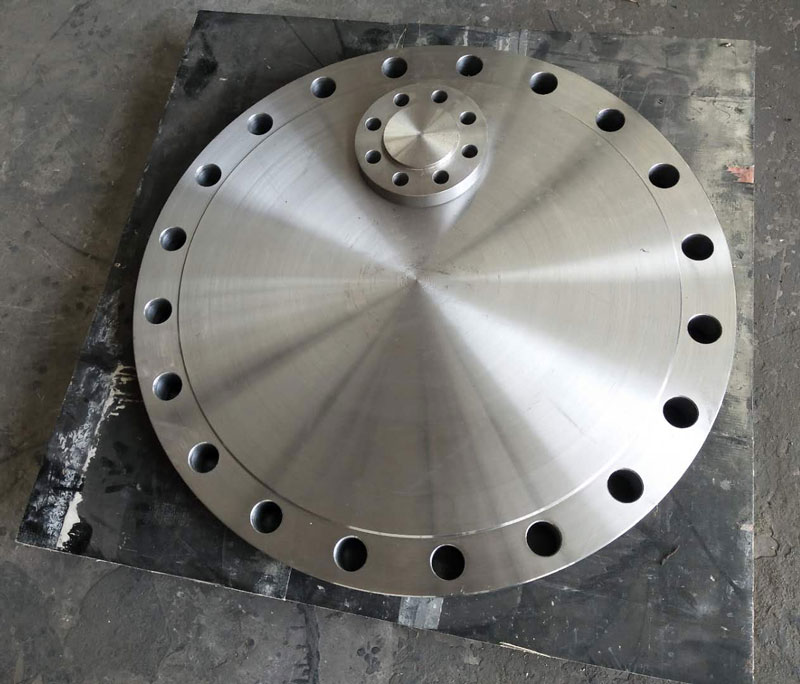

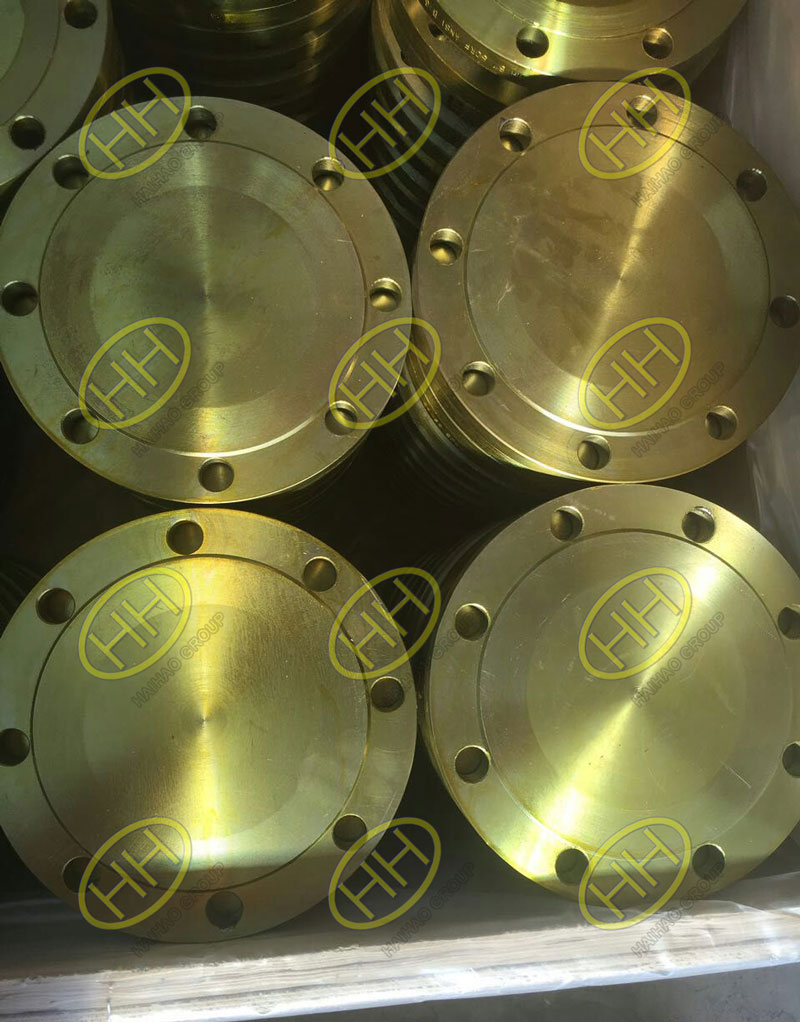

Haihao Group supply high pressure forged flanges more than 30 years,our flange products contain weld neck flange,slip on flange,blind flange,plate flange,threaded flange,socket weld flange,orifice flange,lap joint flange(loose flange),spectacle blind flange,long weld neck flange,reducing flange,rolled forging ring flange,flange olet,tube sheet,anchor flange,non standard flange(custom flange).If you want to know more about our products,please email us:sales@haihaogroup.com