Haihao Group Supplies A105N ASME B16.5 and B16.47 Flanges for Dubai Project

Haihao Group has successfully completed another international delivery, supplying a comprehensive batch of A105N carbon steel flanges for a key industrial project in Dubai, UAE. The order includes multiple types such as jacketed flanges, blind flanges, and weld neck flanges, all precisely manufactured in accordance with ASME B16.5 and ASME B16.47 standards.

Each flange was produced according to detailed drawings provided by the client, ensuring full dimensional and technical compliance. This shipment demonstrates Haihao Group’s strength in customized flange manufacturing for demanding global applications.

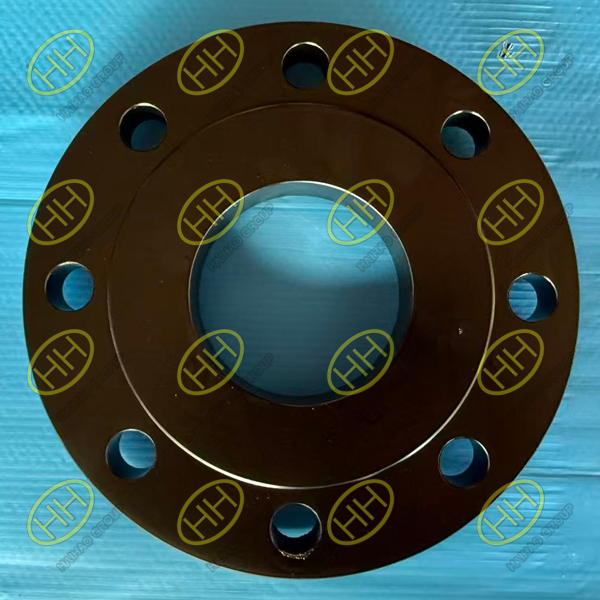

JACKET FLANGE A105N ASME Class 150 SO RF ASME B16.5 manufactured by Haihao Group

Order Overview

-

Products supplied:

-

Jacket Blind Flange 4″–6″, A105N, ASME Class 150 BLIND RF

-

Jacket Flange 4″–6″, A105N, ASME Class 150 SO RF (ASME B16.5)

-

Jacket Flange 3″–4″, A105N, ASME Class 150 SO RF (ASME B16.5)

-

Flange 36″, A105N, ASME B16.47 Series A, Class 150 WN RF (Toxic normalized, NACE MR 0103 compliant)

-

Jacket Flange 4″–6″, A105N, ASME Class 300 SO RF (ASME B16.5)

-

-

Material: ASTM A105N carbon steel

-

Quantity: 47 pieces total

-

Standards: ASME B16.5, ASME B16.47, NACE MR0103

-

Production: Custom fabricated based on client drawings

Precision Manufacturing and Strict Quality Control

Each A105N flange underwent a series of stringent quality inspections, including dimensional verification, surface finish checks, and non-destructive testing (NDT). For the 36-inch weld neck flanges, the chemical composition strictly followed NACE MR0103 requirements, ensuring safe use in corrosive and sour service environments.

The flanges were toxic normalized to improve grain structure and toughness, guaranteeing stability and performance under varying pressure and temperature conditions.

Haihao Group’s advanced manufacturing lines and CNC machining centers ensure consistent precision and repeatability across all flange sizes.

Engineering Expertise in Jacketed Flange Fabrication

The jacketed flanges included in this order were custom-designed to meet specific process temperature requirements in the client’s system. Jacketed flanges are often used in chemical and petrochemical plants, allowing controlled heating or cooling of pipeline sections.

Haihao engineers optimized the welding and machining processes to ensure accurate alignment between inner and outer layers, achieving reliable sealing performance and long service life.

Commitment to International Standards and Global Clients

As a leading carbon steel flange supplier in China, Haihao Group continues to provide ASME and API-compliant flanges to clients across the Middle East, Europe, and Southeast Asia.

This shipment to Dubai further reinforces Haihao’s reputation as a trusted partner in global pipeline system solutions, capable of delivering custom-engineered products on time and to specification.

The successful completion of this A105N flange order for a Dubai project marks another milestone in Haihao Group’s continuous growth in the international market. From design consultation to precision production and quality assurance, Haihao remains committed to delivering high-performance flange products that meet the world’s most demanding industrial standards.