Custom Flanges Manufactured with ASTM A516 Gr.70 Steel for Industrial Applications

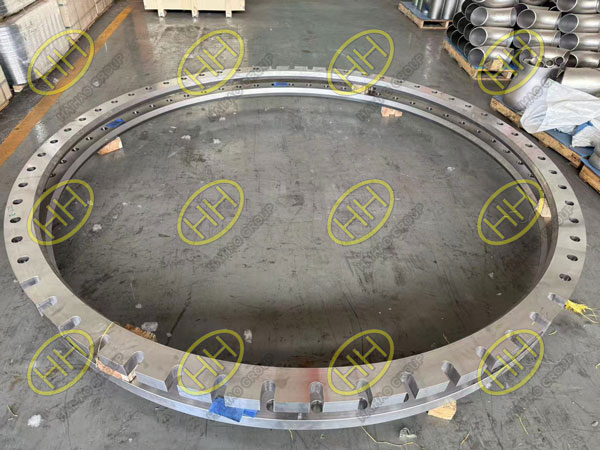

At Haihao Group, every project starts with understanding the customer’s real, technical needs—not pushing standard catalog items. Recently, we produced a batch of custom-designed flanges made from ASTM A516 Grade 70 carbon steel, as per client-provided specifications.

These flanges are not your off-the-shelf products. They were designed based on exact project drawings to meet the unique operational conditions required by the customer, ensuring proper fit and long-term durability in the target application environment.

ASTM A516 Gr.70 Custom flanges produced by Haihao Group

Product Snapshot

Product Type: Custom Flange

Material: ASTM A516 Grade 70 (Pressure Vessel Quality Carbon Steel)

There should be no ciphertext water lines, and the chamfers of the bolt holes must not have burrs

“When clients approach Haihao Group for custom-engineered flanges, especially those destined for critical applications, our commitment to unwavering quality and precision takes center stage. We understand that the integrity of these components begins at the raw material stage and extends through every phase of fabrication.

When utilizing plate materials with a thickness exceeding 25mm, Haihao Group mandates comprehensive ultrasonic inspection of the raw material. The results of this vital examination, which includes the provision of a detailed detection report, must strictly conform to the highly demanding EN 10160 S2, E3 level requirements for internal soundness. Furthermore, to ensure the foundational quality of our carbon steel raw materials, their surface rust level must not exceed the stringent classifications of ISO 8501-1 Class A or B prior to processing.

Crucial for traceability and material assurance, Haihao Group consistently provides EN 10204 3.1 certificates with our products. This certificate serves as a comprehensive testament to the material’s chemical composition and mechanical properties, backed by our internal quality control system.

For any flanges involving welded seams, Haihao Group enforces a 100% Radiographic Testing (RT) protocol. This non-destructive examination confirms the complete integrity of all welds, with acceptance criteria rigorously adhering to ISO 10675-1 Class 1 requirements, signifying an exceptionally high standard for weld quality and flaw detection.

Finally, recognizing that attention to detail extends beyond structural integrity, all flange edges are meticulously chamfered or deburred. This ensures safe handling, eliminates sharp edges that could cause injury or damage, and provides optimal preparation for any subsequent welding or surface finishing processes. This comprehensive approach at Haihao Group defines our dedication to delivering flanges that meet the highest global standards for performance and reliability.”

Why ASTM A516 Gr.70 for These Flanges?

ASTM A516 Grade 70 steel is well known in the pressure vessel and heat exchanger industry for its excellent toughness, weldability, and strength under pressure. For customers operating in environments where durability and resistance to brittle fracture are critical (such as high-pressure pipelines, storage tanks, or chemical reactors), this material is a natural fit.

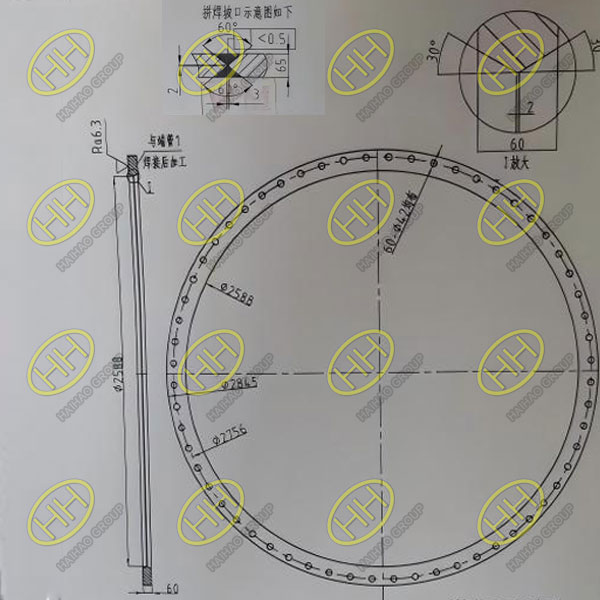

The use of drawing-based manufacturing ensures that every dimension, hole position, sealing surface, and flange thickness matches the customer’s exact design requirements—critical for preventing leaks and ensuring structural integrity in service.

Technical drawing of ASTM A516 Gr. 70 custom flange by Haihao Group

Tailored to Unique Project Requirements

Unlike standard flanges that follow general ASME or EN norms, these flanges were fully fabricated according to the client’s specific technical drawings. This approach provides:

✔️ Exact bolt hole patterns

✔️ Customized sealing face machining

✔️ Thickness matched to system pressure design

✔️ Compatibility with special gaskets or pipeline connectors

By producing directly to client blueprints, we help reduce installation time and avoid on-site adjustments—which can be costly and risky in industrial projects.

Projects requiring non-standard flanges like these are usually tied to special process systems such as:

- Pressure Vessels

- Power Generation Equipment

- Petrochemical Plants

- Heavy Machinery Installations

Haihao Group frequently manufactures these customized flanges for projects in Europe, Southeast Asia, and the Middle East, where strict design adherence is essential.

If your project also requires flanges made to special drawings or non-standard specifications—whether in ASTM A516 Gr.70 or other materials such as stainless steel, duplex, or alloy steel—our team at Haihao Group is ready to help.

We handle everything: material sourcing, cutting, machining, inspection, and certification, all under a strict ISO 9001 quality system. Email:sales@haihaogroup.com

Related Article:

ASTM A105 vs. A350 LF2 vs. A516 Gr.70: How to choose the right flange material?