Advantages and application fields of neck butt welding flange

Flange has good comprehensive performance, so it is used in chemical engineering, construction, water supply and drainage, petroleum, light and light industry, refrigeration, sanitation, plumbing, fire protection, electric power, aerospace, shipbuilding and other engineering fields, but their functions are different.

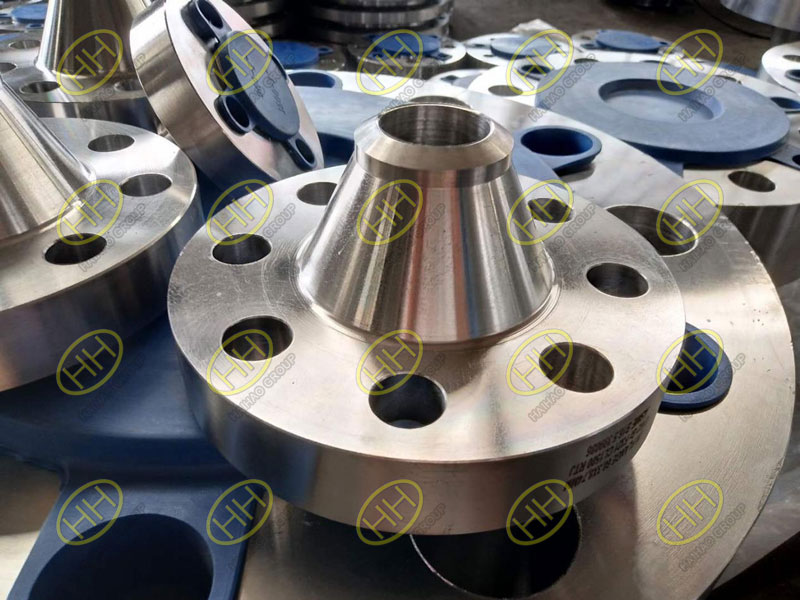

Advantage of neck butt welding flange:

The flange with neck can be subdivided into two main types, namely, flat welding flange with neck and butt welding flange with neck. The flat welding flange with neck can effectively save space and reduce weight, and the most important thing is to ensure that the joint will not leak, and has excellent sealing function; the sealing surface of butt welding flange can be made into three types: lubricating type, high-low type and tenon groove type. The application amount of lubricating flat welding flange is as follows. It is mainly used in the case of medium conditions, such as low-pressure non purified compressed air and low-pressure circulating water. Its advantage is that the quotation is relatively cheap.

Application fields of neck butt welding flange:

There are many types and models of butt welding flange. Butt welding steel flange is used for butt welding between flange and pipe. It is mainly used in welding process. It has good service characteristics and performance, reasonable structure, high strength and rigidity. It needs to be determined according to the specific situation to weld the flange ratio and performance, and can withstand high temperature and high pressure. The application range is determined according to different characteristics. It is mainly used in medium medium medium conditions, such as low-pressure non purified compressed air and low-pressure circulating water. Its advantage is that the price is relatively low. It is suitable for steel pipe connection with nominal pressure less than 2.5MPa. The sealing surface of welding flange can be divided into smooth type, concave convex type and tenon groove type. Among them, flat welding flange is widely used, and butt welding flange of the other two methods is also widely used.

Butt welding flange can withstand high temperature and high pressure, repeated bending and temperature fluctuation. The butt welding flange with nominal pressure of 0.25 ~ 2.5MPa adopts concave convex sealing surface, which is mainly applicable to the environment.

Haihao Group manufacture flange products more than 30 years,the products sells well all over the world for the high quality.If you have any question,please contact us! Email:sales@haihaogroup.com