High-Pressure RTJ Flanges and Spacers for Arctic Pipeline Project

Last month, we prepared and shipped a batch of high-pressure ring-type joint (RTJ) flanges and stainless steel spacer rings for a pipeline maintenance project in a cold-climate zone. The client, an EPC contractor operating in Northern Eurasia, required fittings that could handle both high-pressure operation and sub-zero temperatures down to -29°C (-20°F).

ASME B16.5 A694 F65 RTJ WN Flange Produced by Haihao Group

Items Delivered

The order included the following components:

RTJ Blind Flange, 3/4″, Class 1500, A694-F65, ASME B16.5

RTJ Weld Neck Flange, 3/4″, Class 1500, S/XXS bore, A694-F65, ASME B16.5

Spacer Ring (RF Type), 8″, Class 600, SA240 316/316L, ASME B16.48

All carbon steel components were coated in black paint for basic corrosion protection during handling and storage. The stainless steel spacers were left uncoated as per specification.

Material Selection for Cold Weather

One of the critical requirements for this project was that the carbon steel flanges must be impact-tested at -29°C (-20°F). For that reason, ASTM A694 F65 was selected and the forgings were heat-treated before machining.

We ran Charpy impact tests at the required temperature range to verify notch toughness. Certified test reports were shared with the client before shipment, along with MTRs and full dimensional inspection records.

ASME B16.5 A694 F65 RTJ Blind Flange Manufactured By Haihao Group

Bore and Wall Thickness Customization

The weld neck flange was machined with a S/XXS (Super Extra Strong) bore, which is not a stock option for 3/4″ flanges at Class 1500 pressure. We sourced oversized forgings to ensure proper wall thickness and neck strength could be maintained after custom boring.

This was especially important for ensuring weld integrity in high-stress sections of the pipeline.

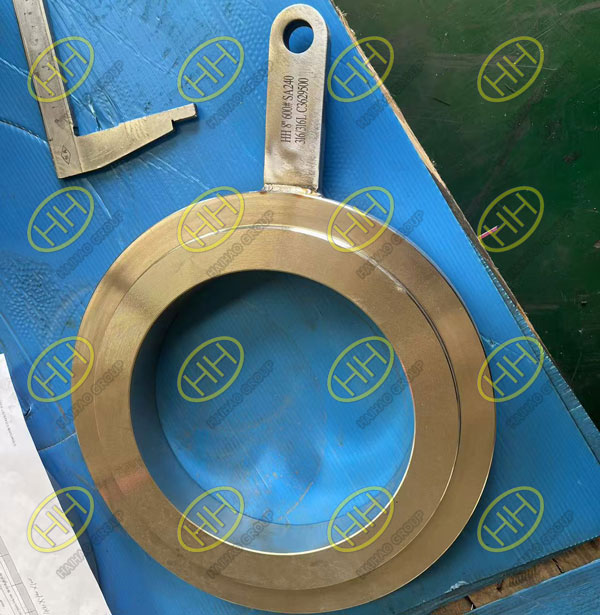

SA240 316L Spacer Ring Machined To ASME B16.48 Standard

Spacer Rings to ASME B16.48

The 8″ spacer rings were machined from dual-certified SA240 316/316L plate. These spacers were designed with raised face (RF) profiles to fit between existing flanged joints. We paid extra attention to flatness and parallelism to avoid misalignment during bolt-up.

Each spacer was laser-etched with material grade, pressure class, and batch number for full traceability on site.

Packaging and Documentation

All components were securely packed using plywood crates with internal cushioning. Flange faces were protected with plastic covers, and custom export markings were added in both English and the client’s requested language.

We provided a complete documentation set including:

- EN10204 3.1 MTRs

- Impact test reports

- Dimensional drawings

- Packing list with heat numbers and flange types clearly labeled

Practical Challenges and Takeaways

The biggest challenge wasn’t the volume—it was getting the specs exactly right. A small flange like 3/4″, Class 1500, with RTJ facing and S/XXS bore is already uncommon. Add to that the need for low-temp impact-tested A694 F65, and the job becomes very tight on tolerances and lead time.

Because we stock raw forgings and do in-house machining, we were able to turn the order around in under two weeks, including testing and certification.

Need Something Similar?

We handle non-standard flanges, custom bores, and pressure-rated components every week. If you need RTJ blind flanges, A694 F65 WN flanges, or spacer rings to ASME B16.48—especially with temperature and testing requirements—we can help without slowing down your schedule.