What is orifice flange?

An orifice flange is used in combination with orifice meters to measure the flow rate of oil, gas and other liquids conveyed by the pipeline. Orifice flanges are manufactured to ASME B16.36 in multiple sizes and, material grades.

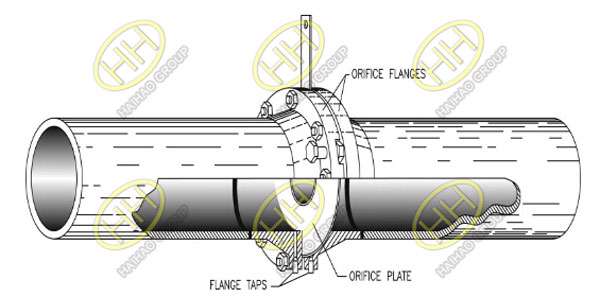

An orifice flange is used to measure the flow of the fluid conveyed by the pipeline via a flow nozzle positioned on the flange itself. Pairs of pressure taps are machined onto the orifice flange, making separate taps on the pipe wall unnecessary.

Orifice flanges are easy to recognize because they have a hole drilled through the face of the flange perpendicular to the pipe. They also have an additional set of bolts called jack screws. These screws are used to help separate the flanges so inspection and/or replacement of the orifice plate can be performed. The orifice flange is a single component of the orifice flange union assembly. The orifice flange union is composed of two orifice flanges, an orifice plate, bolts, nuts, jack screws, and two gaskets.

The orifice plate in the drawing above, which is not typically furnished with the orifice union assembly package, looks similar to a large ring washer with a handle attached. When fully assembled, the orifice plate is sandwiched between the orifice flanges. Valve taps are inserted into pressure holes that allow for the attachment of field monitoring equipment so accurate measurements can be recorded.

Orifice flanges are available in all ASTM forged grades (ASTM A105, ASTM A350, ASTM A694, ASTM 182 respectively for carbon, alloy and, stainless steel flanges), dimensions (combinations of nominal sizes and pressure ratings) and, in socket weld, threaded or weld neck shape (WN is the most used).