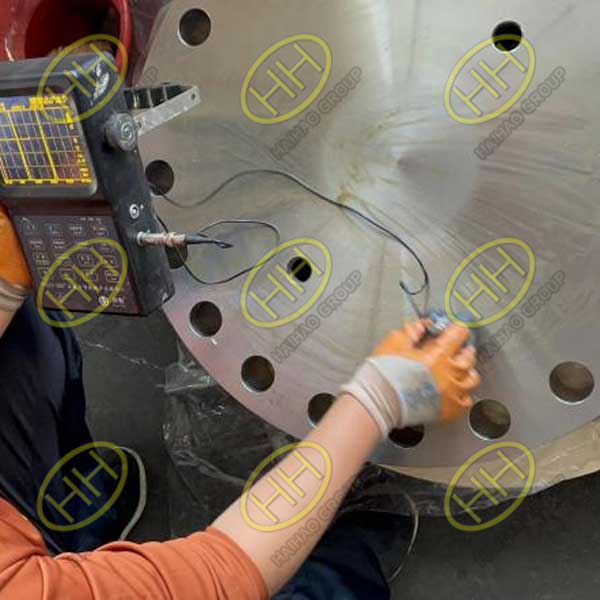

Ultrasonic testing of flanges

Ultrasonic testing is a nondestructive testing method that uses ultrasonic to inspect the internal defects of metal components. Generally, it can be divided into direct contact method and liquid immersion method. Among them, the direct contact method mainly adopts the working principle of A-type display pulse reflection method, which is easy to operate, simple to detect graphics, easy to judge and high sensitivity, and is widely used in actual production.

Ultrasonic testing is widely used in non-destructive testing of flanges, because the structure of flanges is not complex, and the flange surface has a certain degree of finish, these characteristics provide convenience for ultrasonic testing. Ultrasonic testing generally requires experienced inspectors to operate and judge the results. The following is the ultrasonic inspection of the flange conducted by Haihao’s quality inspectors.

Haihao Group has a professional quality inspection team, which can independently complete various tests on products. Our pipe fittings need to pass strict factory quality inspection before leaving the factory, and we support third-party quality inspection. If you need flanges, pipe fittings, steel pipes or other related pipe fittings, please contact us at any time.