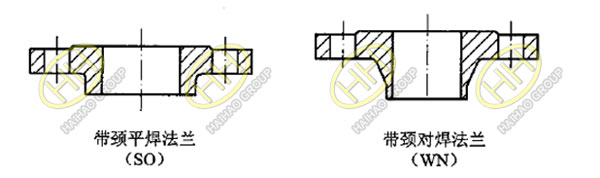

The difference between SO with neck flat welding flange and WN butt welding flange

SO flat-neck welding flange is a recessed platform whose inner hole is slightly larger than the outer diameter of the pipe, and the pipe is inserted into it for welding. WN neck butt welding flange has the same pipe diameter and wall thickness as the pipe to be welded, and it is welded like two pipes.

Flat welding and butt welding refer to the welding method when flanges and pipes are connected. When flat welding flanges are welded, only one-sided welding is required. The internal ports of the welding pipes and flange connections are not required. The welding installation of butt welding flanges requires flanges. Surface welding. Therefore, flat welding flanges are generally used for low and medium pressure pipelines, and butt welding flanges are used for the connection of medium and high pressure pipelines; butt welding flanges are generally at least PN2.5MPa. Butt welding is used to reduce stress concentration. Butt welding flanges are mostly neck flanges, also called high neck flanges, so the installation cost, labor cost and auxiliary material cost of butt welding flanges are higher because of one more process.

The main difference is that the butt weld between the former and the pipe is a fillet weld during installation, and the butt weld between the latter and the pipe is a butt weld. Different weld forms have different pressure-bearing capabilities, so the latter is generally used in high-temperature, high-pressure, and high-risk media situations.