The challenges of manufacturing high pressure flanges: Overcoming difficulties for exceptional performance

High pressure flanges are crucial components in pipelines and other high-pressure systems, commonly used in industries such as oil and gas, chemical, and power generation. These flanges are designed to withstand high pressures and temperatures, ensuring the safe and efficient operation of the system.

However, the manufacturing process of high pressure flanges is much more complicated and challenging compared to low-pressure flanges. This is due to the materials used, the precision required, and the demanding standards that these flanges must meet.

One of the most significant challenges in manufacturing high pressure flanges is the selection of materials. These flanges are usually made from high-strength alloys or carbon steel, which have high tensile strength and excellent resistance to corrosion and wear. However, these materials are often difficult to machine, weld, and forge, requiring specialized equipment and expertise.

Another challenge is the precision required in the manufacturing process. High pressure flanges must be manufactured to exact specifications to ensure that they can withstand the high pressures and temperatures without leaking. Any deviation in dimensions or surface finish can lead to leaks, which can be disastrous in high-pressure systems.

Furthermore, high pressure flanges must meet stringent industry standards, such as ASME B16.5, ASME B16.47, and API 6A, among others. These standards specify the dimensional tolerances, materials, and testing requirements for high pressure flanges. Any deviation from these standards can result in the rejection of the flanges, leading to delays in the project schedule and increased costs.

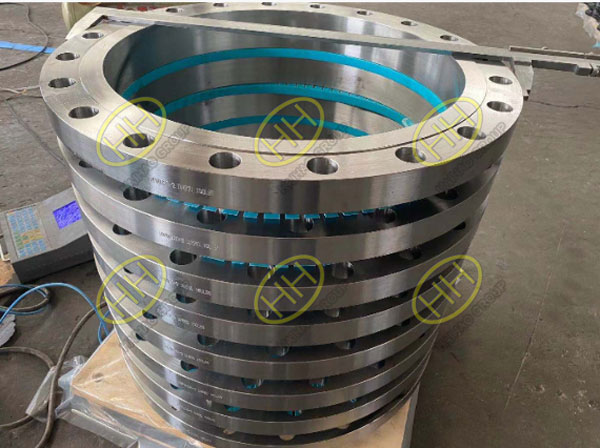

Despite these challenges, Haihao Group has a dedicated team of experts and state-of-the-art equipment to manufacture high pressure flanges with the highest quality and precision. Our flanges meet all relevant industry standards, and we offer a wide range of sizes, materials, and pressure ratings to meet the specific requirements of our customers.

In conclusion, manufacturing high pressure flanges is a complex process that requires specialized expertise, equipment, and materials. However, at Haihao Group, we have the capabilities and experience to overcome these challenges and deliver high-quality flanges that meet the demanding requirements of high-pressure systems.