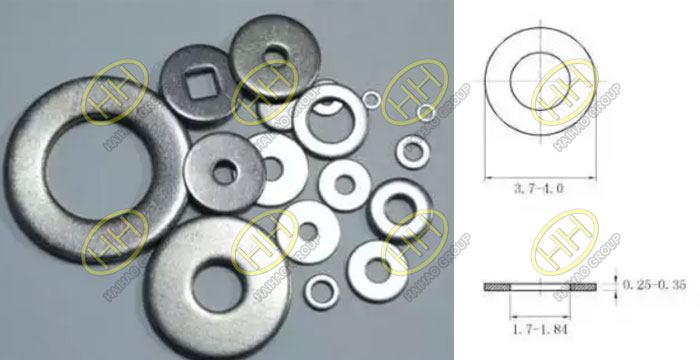

Introduction to flat washer

The flat washer is mainly used to reduce the pressure. When the axial force of some parts is very large, it is easy to make the washer into a disc shape. At this time, it can be solved by using materials and improving the hardness.

The locking effect of the spring washer is general, and the important parts are used less or not as much as possible, and the self-locking structure is adopted. For the spring washer used for high-speed tightening, it is better to use the washer with surface phosphating treatment to improve its wear reduction performance, otherwise it is easy to burn or open the mouth due to friction and heat, or even damage the surface of the connected parts. For sheet joints, spring washer construction shall not be used.

For spring washer and elastic washer, 60, 70 steel and 65Mn Steel in gb699-1999 “high quality carbon structural steel” can be generally selected according to the national standard.

There are nine standards for flat washers in China. Standards for flat washers such as GB / t97.3-2000, GB / t5286-2001, GB / t95-2002, GB / t96.1-2002, GB / t96.2-2002, GB / t97.1-2002, GB / t97.2-2002, GB / t97.4-2002 and GB / t5287-2002 have been approved and issued respectively from 2000 to 2002.

According to the performance grade of flat washer, the recommended material is:

ST12, ST13, Q235, Q215, Q195, etc. can be selected for 100hv, and the surface hardness can reach about 110hv;

For 140hv, 08F, 08Al, 10, 10F and so on can be selected, and the surface hardness can reach about 140hv;

For 200hv and 300hv grades, 45, 50, 60, 70 steel or 65Mn steel shall be selected, which can meet the technical requirements of 200-300hv and 300-400hv through heat treatment, quenching and tempering.

As a professional supplier of pipe fitting, we have more than 30 years of experience in this industry. If you have any problem, please contact me.Email:sales@haihaogroup.com