Heat treatment technology of welding neck flange

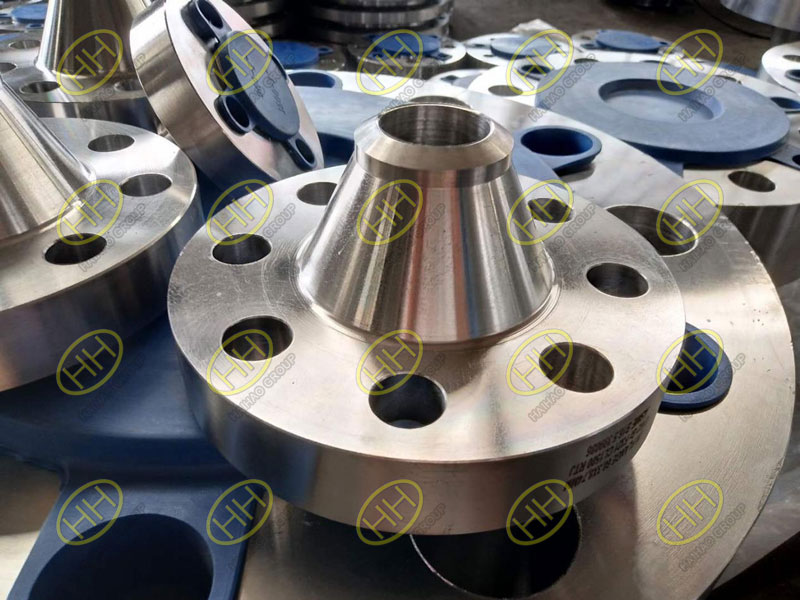

Welding neck flange with neck is a steel hot pressing or forging flange. Its connection form is to directly butt weld the flange and steel pipe, so as to change the angle and direction of two pipes.

The main manufacturing standards of neck Welding neck flange are generally GB / t12459, GB / T13401, asmeb16.9, sh3408, sh3409, Hg / t21635, Hg / t21631, SY / t0510 and GB / t10752-1995.

The outer slope of neck Welding neck flange shall not be greater than 7 degrees. The technical parameters of welding flange are strictly controlled in production and welding to ensure the full play of its role and value in production and use.

The neck welding neck flange needs normalizing + tempering heat treatment and machining port, and the wall thickness needs to leave burning loss and machining allowance. The general allowance is 10% – 20% of the theoretical wall thickness of the flange. The smaller the ratio of the flange wall thickness δ to the section diameter D, the better the adhesion between the flange and the die, but the easier the flange inner arc is to become unstable and wrinkled.

According to the characteristics that the volume of metal remains unchanged during plastic deformation, the wall thickness remains unchanged during push forming (actual slight thinning), and the length of outer arc of flange is equal to the length of tube blank, the formula of outer diameter of tube blank is deduced: if the outer diameter of tube blank selected is smaller than the DP value calculated by the formula, the fitting performance with the die is good, but the inner arc of flange is prone to instability and wrinkling.

If the actual diameter of the tube blank is larger than the DP value calculated by the formula, the result is just the opposite. The principle of determining the heating temperature of carbon steel flange is that the austenitizing temperature of the material is above, and the main pressure of the flange inner wall should be less than the yield force of the material at this temperature. The higher the austenitizing temperature is, the higher the heating temperature is; the higher the high temperature yield force is, the higher the heating temperature is.

Haihao Group manufacture flange products more than 30 years,the products sells well all over the world for the high quality. If you have any question,please contact us! Email:sales@haihaogroup.com