Haihao Group Supplies Carbon Steel, Stainless Steel and Nickel Alloy Flanges to UAE Customer

Haihao Group has successfully completed the shipment of a diversified batch of ASME B16.5 flanges for a customer in the United Arab Emirates (UAE). The order includes carbon steel flanges, stainless steel flanges, and nickel alloy flanging components, manufactured in strict accordance with project-specific requirements for material heat treatment, low sulfur and phosphorus control, and furnace test coupons.

These flanges are designed for use in oil & gas, refinery, and industrial piping systems, where reliability, material integrity, and compliance with international standards are critical.

Carbon Steel Flanges – ASTM A105N

The shipment includes multiple raised face (RF) carbon steel flanges manufactured from ASTM A105N, suitable for medium- and high-pressure pipeline connections.

Supplied types and specifications include:

-

Weld Neck (WN) RF flanges: 2″–6″, Class 150 / 300, SCH 40 / SCH 80

-

Long Weld Neck (LWN) RF flange: 2″, Class 300

-

Socket Weld (SW) RF flange: 3/4″, Class 300, SCH 160

-

Slip-On (Lap Joint) RF flange: 3/4″, Class 300

-

Blind (BL) RF flanges: 4″ & 8″, Class 150

All ASTM A105N flanges were supplied with guaranteed heat treatment and low sulfur and phosphorus content (S < 0.02%), ensuring improved toughness and weldability.

A furnace test coupon (30 × 30 × 120 mm) was provided with the batch to support mechanical and chemical testing.

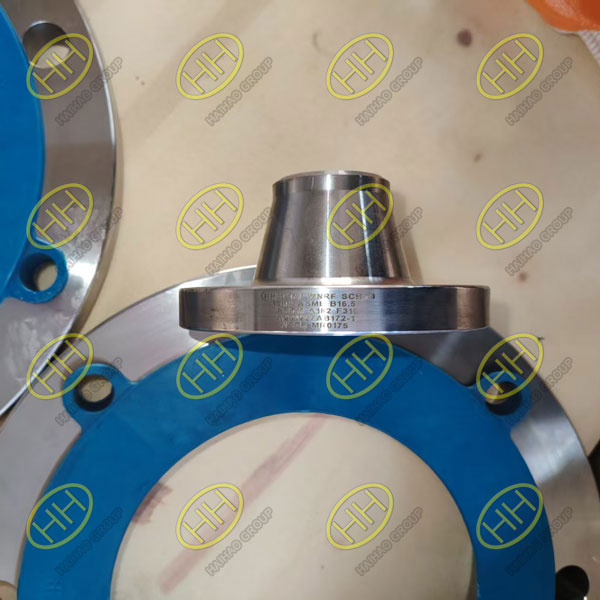

ASTM A182 F316 stainless steel and UNS N08825 nickel alloy supplied by Haihao Group

Stainless Steel Flanges – ASTM A182 F316

For corrosion-resistant applications, Haihao Group delivered ASTM A182 F316 stainless steel flanges, widely used in aggressive service environments.

Included items:

-

Slip-On (SO) RF flanges: 8″, Class 150 & Class 300

-

Weld Neck (WN) RF flange: 1-1/2″, Class 150, SCH 40

-

Stainless steel test coupon: 30 × 10 × 100 mm

All A182 F316 flanges underwent specified heat treatment, with low sulfur and phosphorus control, and test coupons were prepared in advance for mandatory inspection and testing.

The production schedule was strictly controlled to meet a 10-day delivery requirement.

Nickel Alloy Flanging Components – ASTM B366 UNS N08825

The order also includes nickel alloy UNS N08825 (Incoloy 825) flanging components, designed for highly corrosive and chemically aggressive environments.

Supplied items:

-

Stub End (Lap Joint / Flanged End): 3/4″, wall thickness 3.91 mm

-

Test coupon: 35 × 35 × 100 mm

Manufactured to ASTM B366 and ASME B16.5, UNS N08825 offers excellent resistance to acids, chlorides, and stress corrosion cracking, making it suitable for demanding UAE industrial applications.

Quality Control and Project Assurance

To meet UAE project standards, Haihao Group ensured:

-

Strict compliance with ASME B16.5 dimensional requirements

-

Full material traceability for all flanges

-

Controlled heat treatment for each material grade

-

Low sulfur and phosphorus content verification

-

Furnace test coupons and pre-shipment testing readiness

These measures help guarantee long-term performance and reliability in critical piping systems.

Reliable Flange Supplier for UAE and Middle East Projects

With extensive experience supplying ASME B16.5 flanges to the Middle East, Haihao Group continues to support UAE customers with carbon steel, stainless steel, and nickel alloy flange solutions tailored to project specifications.

From standard weld neck flanges to corrosion-resistant alloy components, Haihao Group remains a trusted partner for demanding industrial applications.