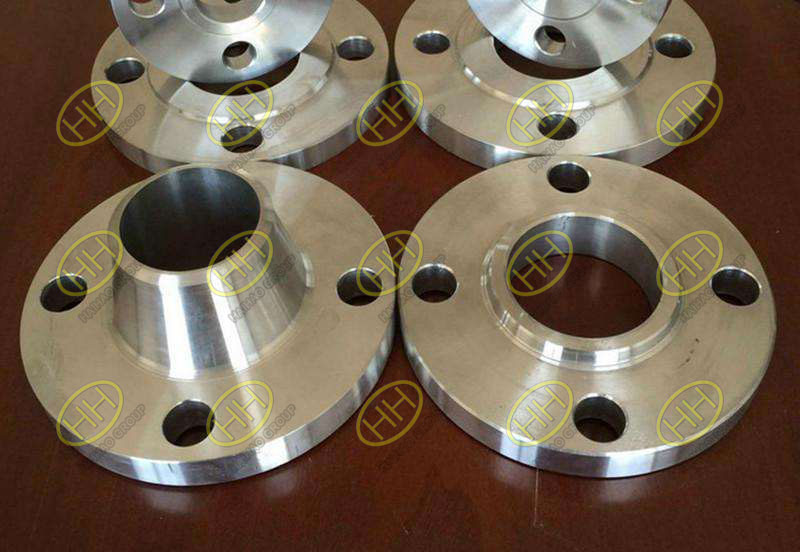

Comparison of butt welding flanges with neck and flat welding flanges with neck

Butt welding flange is the flange with neck and round pipe transition,and it’s connected with the the pipe by butt welding.Plain welding flange(flat welding flange) is a kind of flange which is connected with vessel or pipeline by fillet weld.The comparison of butt welding flanges with neck and flat welding flanges with neck as follows:

They have different weld forms: flat/plain welding flange can not be detected by X-ray,but can be welded.The welding seam between flanged pipe and flange with neck is fillet weld,flat weld is two fillet girth,butt weld is a butt girth.The welding seam of butt welding flange with neck and pipe is circumferential weld;the difference between flat welding flange with neck and flat welding flange without neck is that there is more flange with neck than that without neck flat welding flange in pipeline welding.Flat welding flange without neck is flat-angle flange,and flange without flange is also flat-fillet weld.The welding seam between butt flange and nozzle with neck belongs to Class B seam,while the welding seam between flat flange with neck and nozzle belongs to Class C seam.The non-destructive testing after welding is different.

They have different materials: the flange with neck flat welding is processed by ordinary steel plate with the required thickness,while the flange with neck butt welding is mostly machined by forged steel parts;

Their connection modes are different: the biggest difference in structure between flanges with neck and butt welding flanges with neck is the connection mode between nozzle and flange. Flanges with neck are generally nozzle and flange corner joints,while flanges with neck butt welding are flange and nozzle butt joints.

The nominal pressure is different: the nominal pressure of flange with neck is 0.6-4.0 MPa,while the nominal pressure of flange with neck is 1-25 MPa. Obviously, the adaptable pressure level of flange with neck is lower.

Flat-welded flange can only be connected with pipeline,but not directly with butt-welded pipe fittings;butt-welded flange can be directly connected with all butt-welded pipe fittings (including elbow,tee,diameter pipe etc) of course,including pipelines.

The stiffness of butt-welded flange with neck is higher than that of flat-welded flange with neck,and butt-welded flange has higher strength than flat-welded flange,so it is not easy to leak.

Flange with neck and flange with neck butt welding can not be replaced casually.In terms of manufacturing angle,flange with neck butt welding (SO is abbreviated as slip on) has large inner longitude,which means small weight and low cost.In addition,flange with neck welded (WN is abbreviated as weld neck) with nominal diameter greater than 250mm needs to be tested.Flange with SO does not need to be tested,so the cost is relatively low.

Haihao Group supply flange products more than 30 years,which contain butt welding flanges,plain/flat welding flanges and forged flanges,and our products according to international standards such as ANSI/ASME,API,BS,DIN,EN,JIS,ISO,GOST,UNI,MSS etc.If you want to know more about our products,please feel free to contact us email:sales@haihaogroup.com